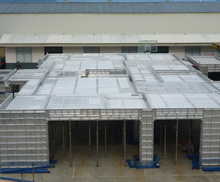

About Aluminium Formwork

Aluminium formwork is a construction system for forming cast in place concrete structure of a Building. EINS Technik Formwork system provides Aluminium formwork for RCC, load-bearing, multi-storeyed buildings and enables the walls and slab to be poured in the same operation. This increases efficiency, and also produces an extraordinarily strong structure with excellent concrete finish.

What is An Aluminium Formwork?

- Aluminium formwork uses panels that are made from high strength Aluminium alloy.

- The panels are held in position by a simple pin and wedge arrangement system.

- The panel fits precisely, securely and requires no bracing.

- It has sections that are large enough to be effective, yet light enough in the weight to be handled by a single worker.

Necessity of Aluminium Formwork System

- Rapid urbanization has resulted in a geometric increase in the housing demand, which cannot be fulfilled using conventional methods of construction.

- The traditional method of construction for mass housing & high rise buildings is a slow process and has limited quality control, particularly when a large size project is involved.

- It is therefore obligatory to work out a method where the speed and quality of construction are controlled automatically by a systematic approach.

Why Aluminium form

- Unsurpassed construction speed.

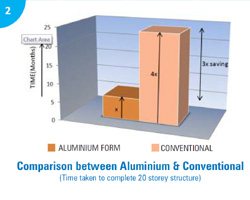

- Savings on overhead expenses due to speedy construction (6-7 days per floor).

- Eliminates plastering

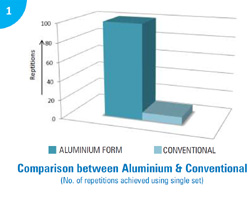

- Panels can be reused up to 300 times.

- Monolithic crack free structures.

- High quality finish.

- Doesn't require timber or plywood for construction activities (Eco-friendly).

- Casting of walls and slabs possible simultaneously

- Minimum requirement of skilled labor.

- Increased Earthquake resistance

Features

Speed

Ease in Shuttering / de- Shuttering and ability to perform monolithic concreting for any structures gives “EINS Technik Formwork System” a superior advantage of speed. Using EINS Technik Formwork System technology floor to floor cycle of seven days can be achieved.Quality

“EINS Technik Formwork System” is manufactured with precise tolerance providing High quality Formwork components which ensures the consistency of architectural dimensionsSafety

A lot of importance is given to safety while designing the “EINS Technik Formwork System” External brackets are provided which are fixed along the periphery of the structure at two levels for safe Erection and De- Shuttering of External Formwork.Ease of Erection & De – Shuttering

A lot of Emphasis is given to the erection and De- Shuttering time of Formwork. Vertical and Horizontal members are locked through pins and Wedges. Vertical Formwork Components can be removed in 24 Hours and Horizontal Formwork Components can be removed in 72 Hours without disturbing the props so that the Formwork Components can be used for the Subsequent floors with second Set of Props.Easy Material Handling

Light weight of the system ensures smooth flow of the component without the use of any External material Handling Equipment such as cranes and super decks as the Formwork Components can be easily transported to next level by a single person manually.Highly Versatile & Durable

High Quality Aluminium alloys are used to manufacture “EINS Technik Formwork System” with the highest standards of manufacturing methods and practices enabling the consumer to achieve as many as 300 usages, under Ideal conditions and proper handling.Less Dependency on Skilled Workers

“EINS Technik Formwork System” is made of lightweight Aluminium alloy which allows the big and small components to be hand carried and setup. Due to the elaborate Design and Drawings provided to the clients, erection old formwork can be achieved by unskilled workers with ease and accuracy.

Advantages of Aluminium Shuttering

India and the developing World’s facing a huge shortfall in housing, and also the need for massive infrastruture development ,technologies like “EINS Technik Formwork System“ Play critical role. The most important aspect of a successful structural construction is the Right Formwork Associate “EINS Technik Formwork System” offers Most Trusted, Safe Efficient and Cutting Edge Formwork System Techn available in the market globally .

Advantages Over Conventional Formwork

- Faster completion.

- Reduced effective cost.

- Higher carpet area.

- More seismic resistance.

- Increased durability.

- Lesser number of joints.

- Uniform quality of construction.

- Negligible maintenance.

- Lesser manual labor.

- Better sound transmission coefficient.

- Integral and smooth finishing of wall and slab.

Formwork Type – Comparison

Characteristics

- Requirement of Heavy lifting equipment

- Able to cast Columns, beams walls and slab in single cast

- Remove floor slab formwork without moving props

- Minimal skilled labor required

- Formwork equipment adepts to different designs

- Lowest formwork to forming area ratio

- Accurate dimensioning provide unmatched forming accuracy Environment Friendly

Traditional Formwork

- Yes

EINS Technik Formwork Formwork System

- Yes

- Yes

- Yes

- Yes

- Yes

- Yes